Design Automation Solution

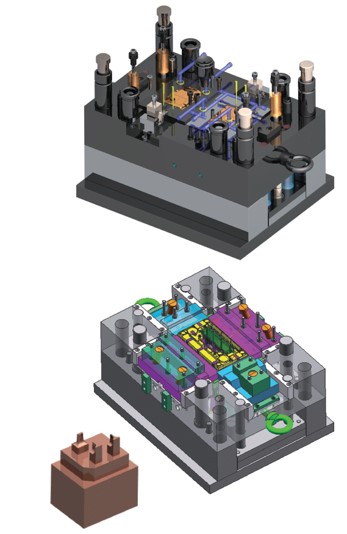

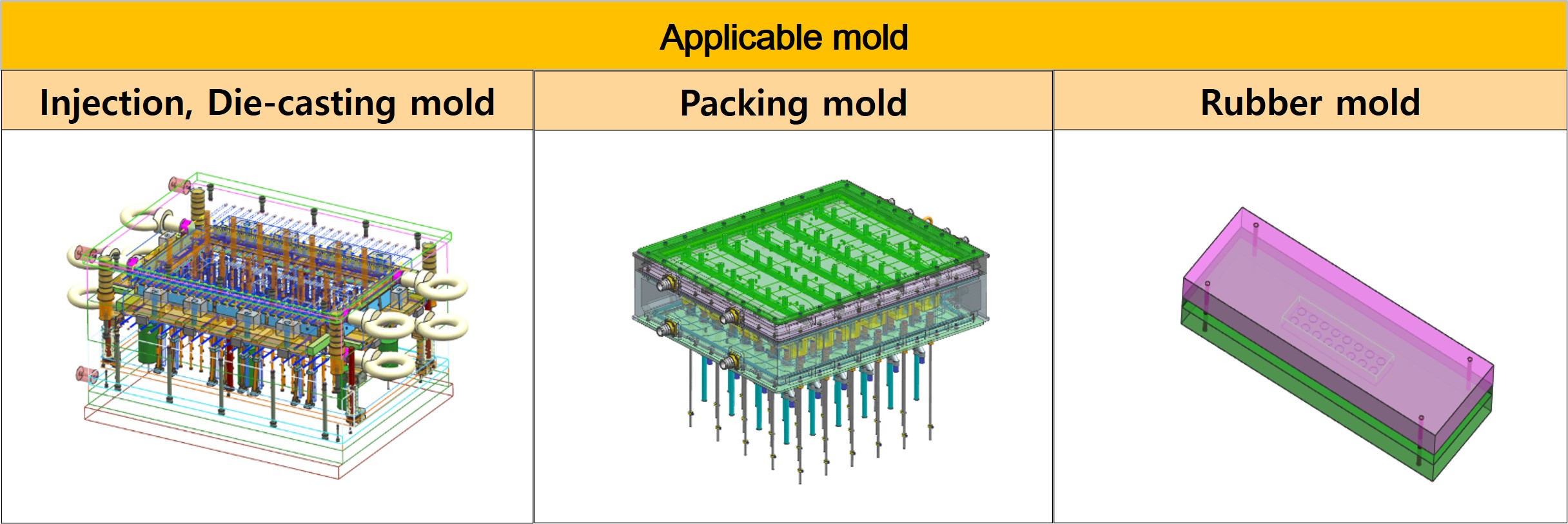

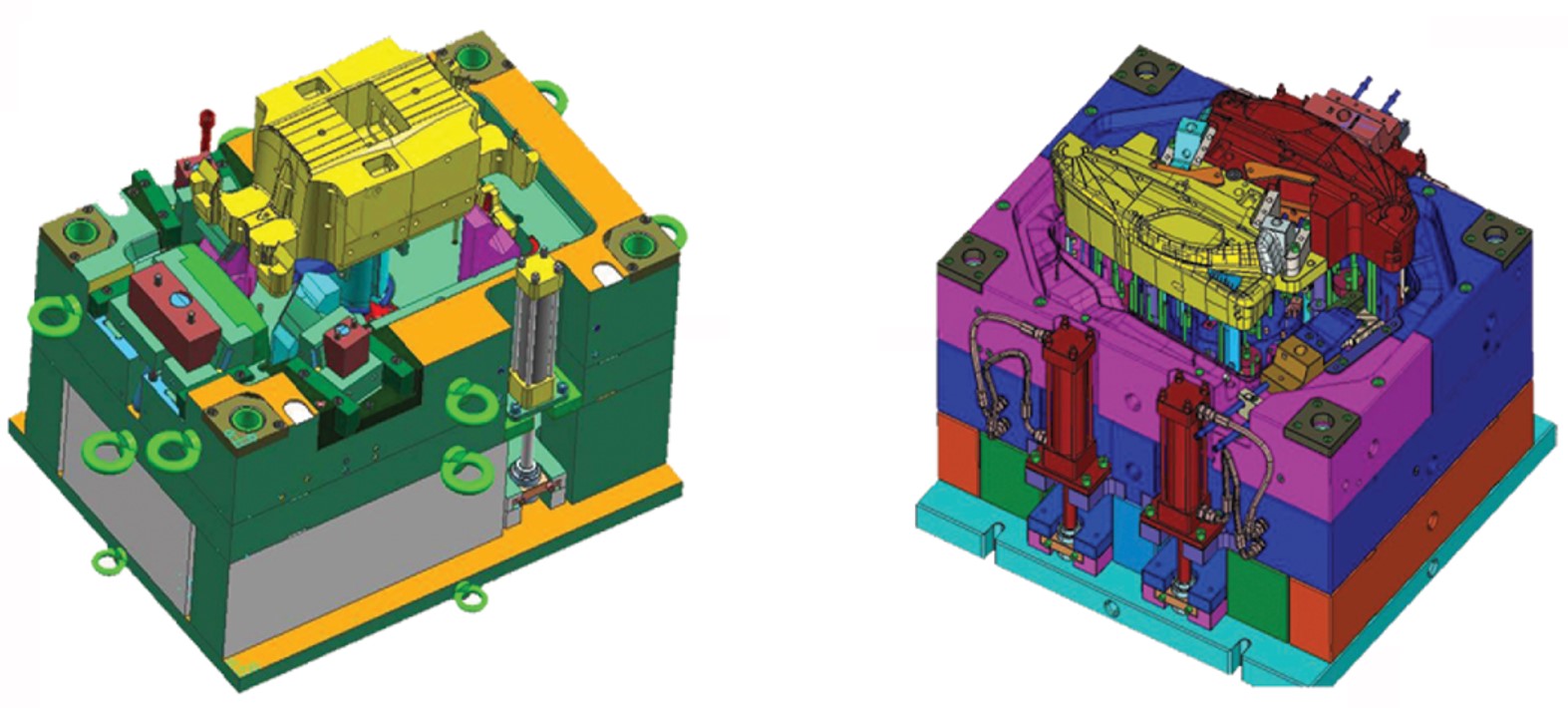

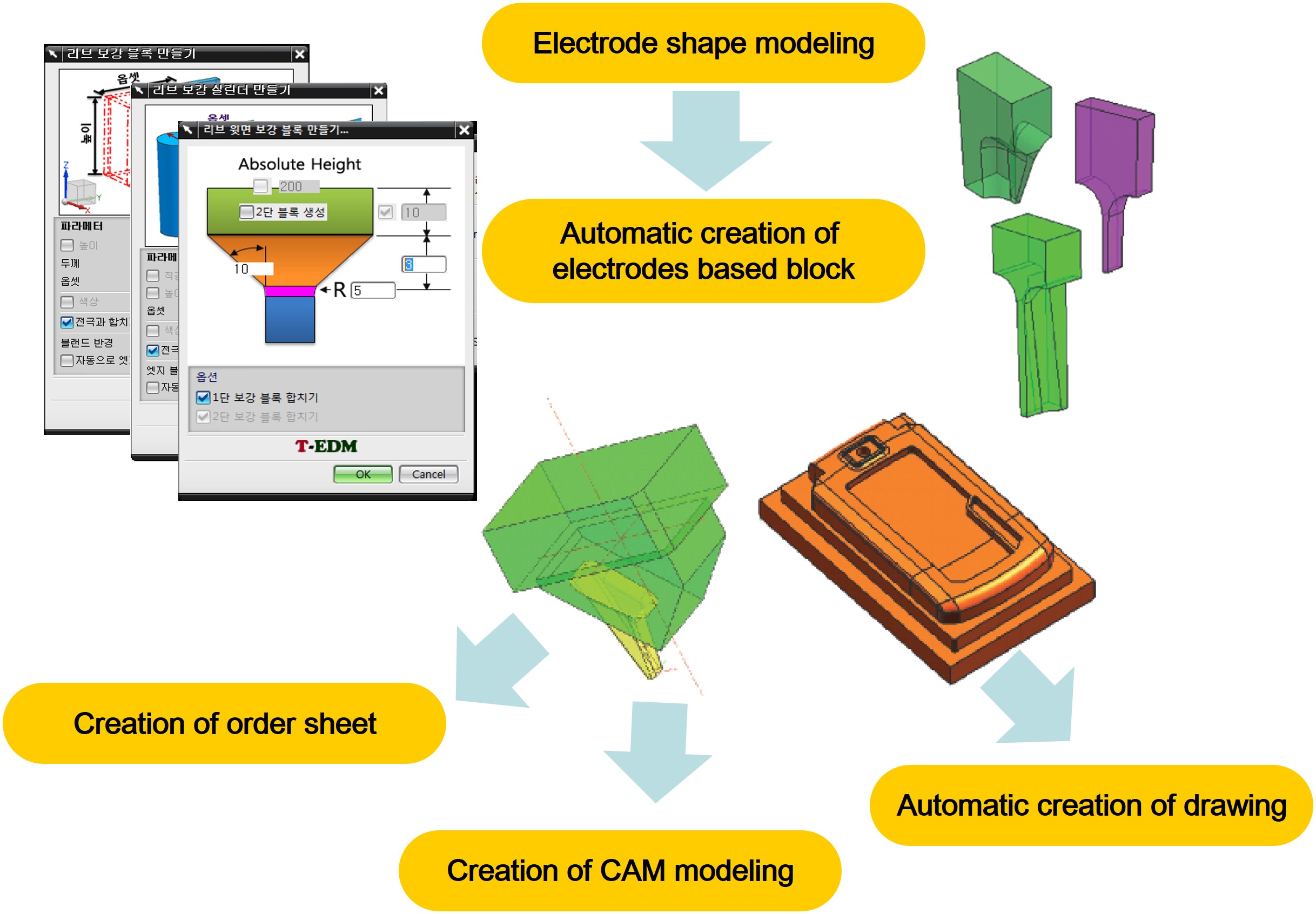

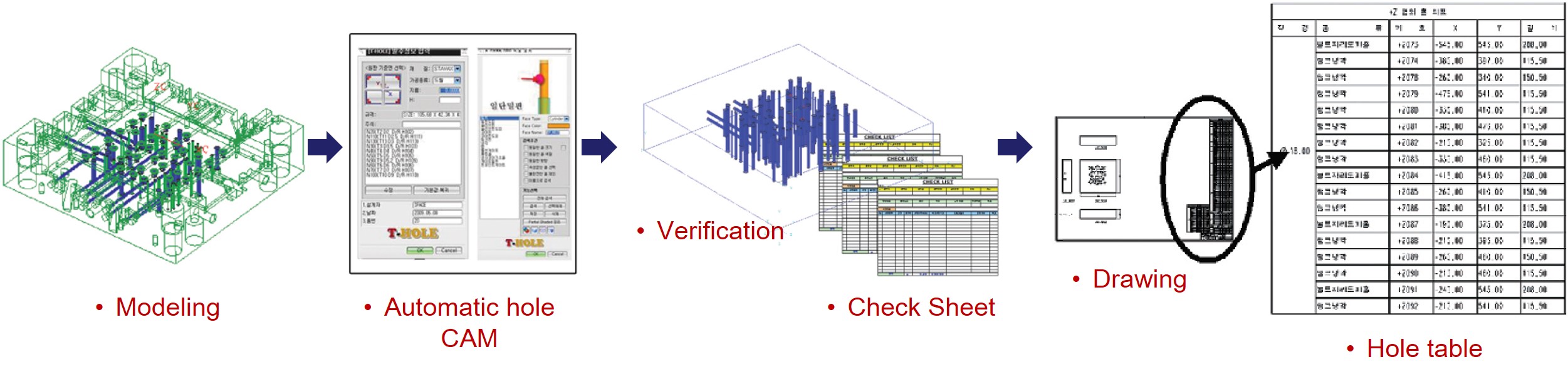

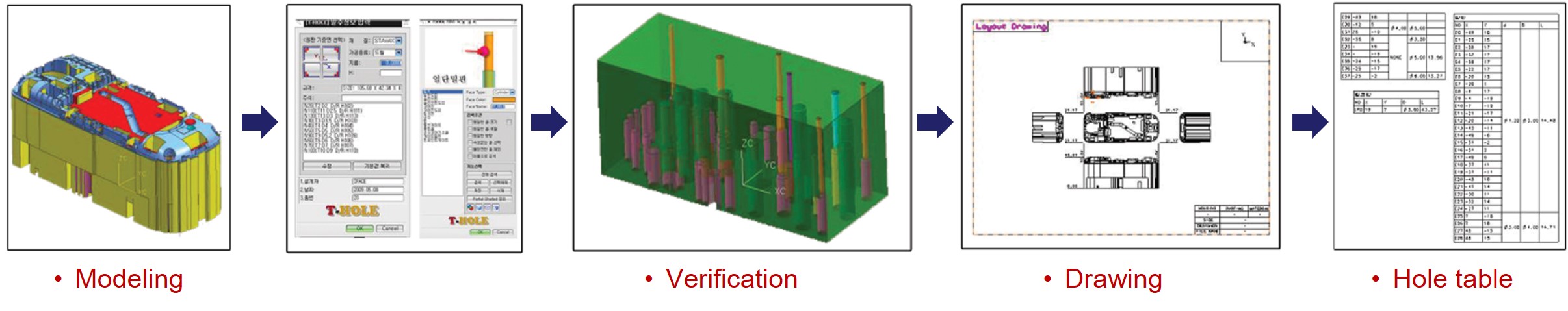

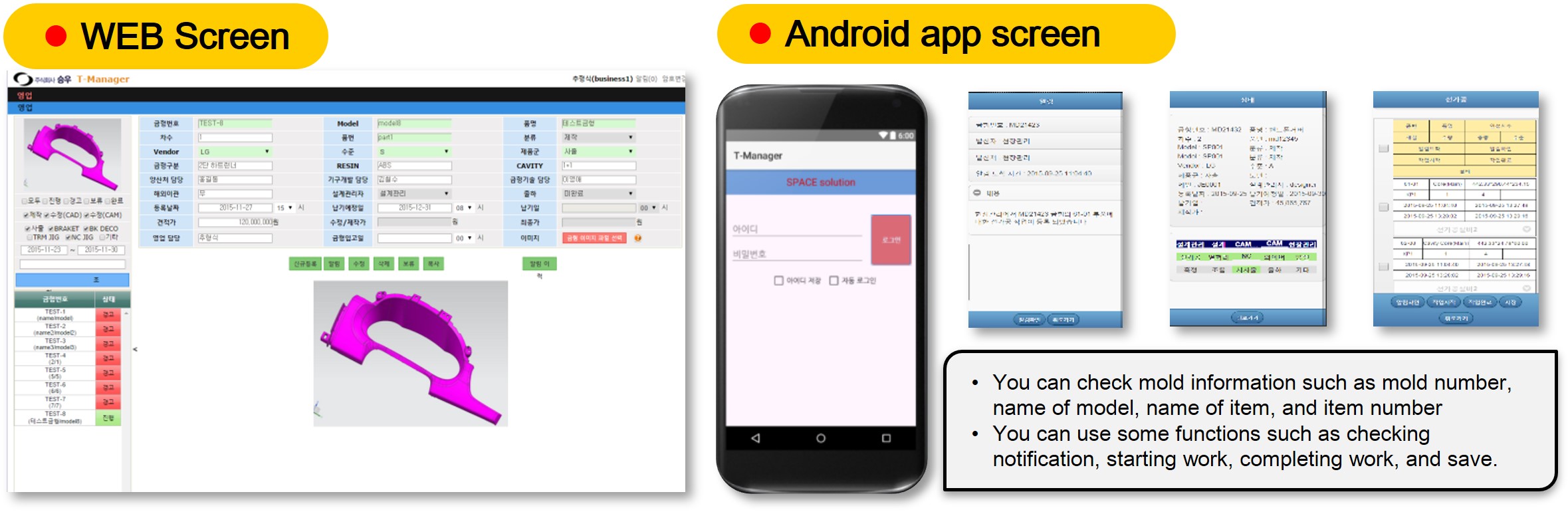

We propose an innovative 3D mold design automation solution. By applying evolved 3D modeling technology to mold design, our industry has achieved new technical innovation.

SPACE Solution incorporates its knowledge and experiences in mold industry and NX modeling to T-Solution to develop the optimized automation solution more advanced than the existing 3D design system.

Our technical support team is composed of fully experienced workers in the mold industry and NX technology. Therefore, they understand users' difficulties and needs, making their best to improve technology of our clients through customized education and high standard technical support.